Logistics is a complex sector, which can profit with the help of Internet-of-Things technologies. With IoT devices, the process of storage at the warehouse and shipping from port to manufacturer and end customer will be more organized and cost-effective. Read on to learn about problems in logistics, the solutions that IoT offer, and the outcomes of its implementation.

How IoT Can Improve the Logistics Industry

Present and Future of Logistics

The global market has witnessed a rapid growth of e-commerce in recent years, and logistics has had to handle the increased demand, along with insufficient personnel and low profits. The burning issue today is to find new ways to optimize major procedures so they can face the upcoming challenges. Internet-of-Things cutting-edge methods will simplify process and make it more efficient.

Get SaM Solutions’ IoT consulting or development services to deliver a competitive IoT product cost-effectively.

Major Problems in Logistics

The logistics processes are fairly complex and usually include several stages that require close attention and constant enhancement. Let’s consider the parts of logistics process that can benefit from extensive implementation of IoT:

- Storage and warehousing

- Planning, wrapping

- Inventory management

- Control of transportation

As the industry evolves, new issues emerge, caused by external factors such as the latest international market trends, higher customer requirements and skyrocketing demand.

Analog Channels

One of the pressing challenges is that despite omnipresent digital technologies, companies still frequently get their orders through analog channels. In this context, it is more difficult for them to record shipment details and process orders quickly and efficiently.

Dedicated Time Booking

Clients of logistics companies are eager to book specific time windows for product pick-up and delivery. As a rule, they have to book dedicated time in advance, usually 24 hours before the interaction. When a definite time is scheduled, it is difficult to change afterward, which causes significant inconveniences for companies as the intended pick-up or delivery window becomes less flexible.

Barcode Recording

Customers want to monitor the current shipping status of their goods so that they are not lost, for example, on their way from the port to the warehouse or manufacturer. This level of transparency has become a real challenge for companies. Conventional barcode scanning procedures are inefficient because they are time-consuming. Transportation systems are not suitably equipped to provide this information to the client on a regular basis.

Transfer of Shipping Information

If logistics companies do not transfer their shipping information, it has to be transferred by the service provider, which can lead to incorrect recording of information. The situation is aggravated by a lack of qualified specialists. As a result, shipments are not reloaded on time due to the absence of recorded shipping data, which disrupts smooth delivery.

The Advantages of IoT for Logistics

IoT devices can collect and transmit data via sensors and actuators, scalable cloud solutions, and user-friendly communication networks. The advantages of IoT technologies for the logistics sector are:

- monitoring the state of a driver and vehicle

- real-time object identification and tracking

- ensuring proper storage conditions and product safety

- effective data transmission

- avoiding media breaks thanks to extensive digitization

- delivery time estimation

- remote control of the transportation process.

With IoT, old-fashioned supply chain patterns are left behind and the operational efficiency of the sector is increased. In terms of communication, there will be no more media breaks thanks to extensive usage of real-time digital interaction instead of such analog methods as phone, paper and fax. As a result, the transportation costs, resource allocation and the entire shipment process are significantly optimized.

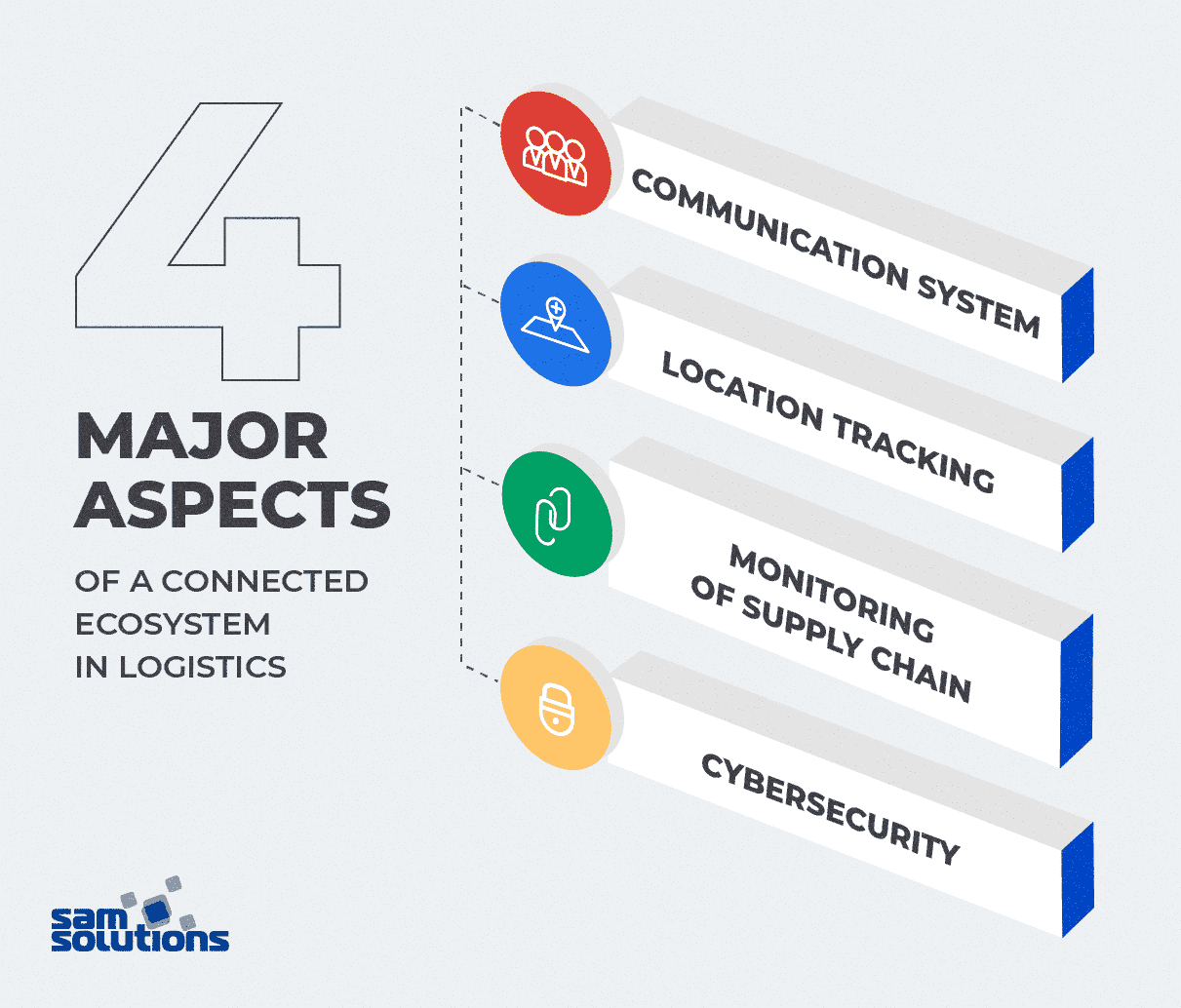

4 Major Aspects of a Connected Ecosystem in Logistics

Even before the emergence of IoT technology, the logistics sphere used connected ecosystems to monitor the process of delivery to guarantee timely shipment to remote locations. There are four major aspects of the connected ecosystem:

1) Communication System

The communication system facilitates continuous communication between drivers and managers. Usually, the main means of interaction between them are cell phones, which often lack the appropriate quality of connection.

2) Location Tracking

GPS devices are used to track the specific location of vehicles at a given moment in time. These tracking tools help logistics industries calculate the estimated delivery time and monitor the tracks on the way to the warehouse, port, or ultimate destination.

Leverage the latest IoT technologies with our expert team and get powerful IoT solution for your business.

3) Monitoring of the Supply Chain

Supply chain real-time monitoring systems play an important role in the industry. These instruments help companies streamline the entire supply chain process, including acquisition of raw stuff and shipping of ready-to-use products.

4) Cybersecurity

The transportation industry has to handle various IT security threats, the number of which has amplified recently. Hacker attacks on confidential data can affect not only companies, but also third-party vendors and the end clients.

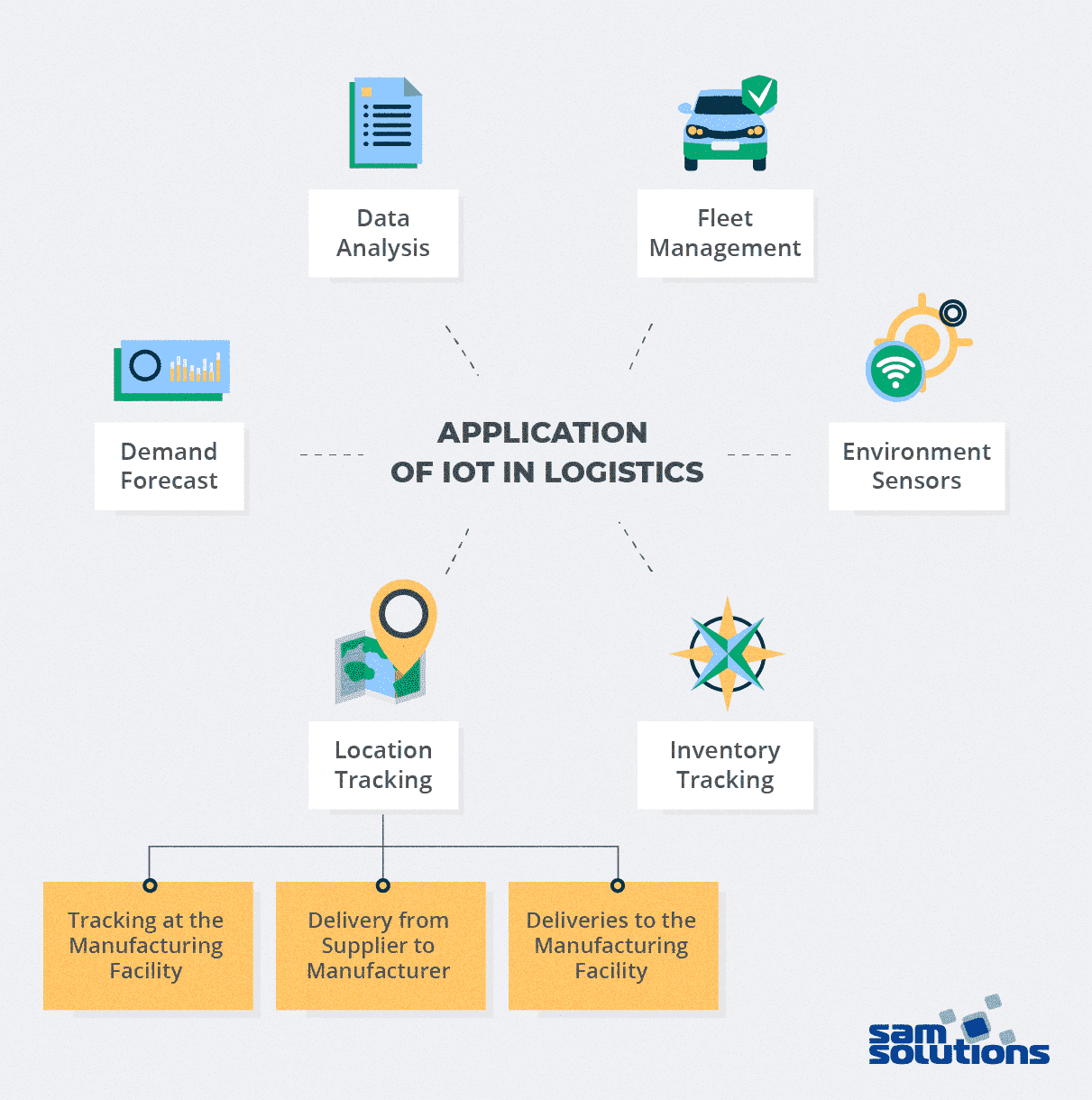

Applications of IoT in Logistics

Location Tracking

Delivery from Supplier to Manufacturer

A real-time location system (RTLS) is used to track the delivery of materials from each vendor to the producer. It is especially beneficial where there are multiple vendors — if the delivery from one vendor is postponed, you can substitute it with another vendor’s services.

Deliveries to the Manufacturing Facility

With RTLS, it is easier for truck drivers to unload the products at the correct place, avoiding product loss and wrong delivery. Similarly, for the manufacturer, it is easier to locate and pick up the products.

Tracking at the Manufacturing Facility

When materials arrive at the factory, they can be mixed up by mistake, which can lead to wrong cycle times and disrupted production. Thanks to RTLS, it is always possible to tell the exact location of the tagged goods and ensure correct manufacturing procedures.

Environment Sensors

To keep sensitive goods fresh and maintain their quality, certain environmental requirements need to be fulfilled. There are special IoT apps that help tag products and monitor a number of environmental characteristics. For example, they can check the humidity, light, and temperature, as well as shock and vibration exposure during transportation to and from the port, manufacturer, or warehouse. This data can be used to notify the managers of damaged goods before they reach the factory or end customer.

Data Analysis

Sensors collect huge amounts of data on a daily basis. To structure and analyze this data properly, IoT tools can be used. With these instruments, managers can implement predictive maintenance, make more efficient decisions, and improve the warehousing and shipping process.

Fleet Management

Timely updates on the driver’s health, vehicle state and traffic conditions give insight into how to improve fleet management strategies. Thanks to this information, specialists can get a clear view of how the resources are used and create new ways to increase efficiency. Implementation of IoT can help reduce delivery time, fuel costs, and streamline car maintenance.

Demand Forecast

The application of IoT in logistics can also help keep up with demand, which facilitates effective supply chain management. Smart technologies can predict demand based on a comprehensive analysis of multiple factors such as user behavior, current market trends, customer intention and preferences, the reasons why the buyers make the purchases, and how they use the goods afterward.

Inventory Tracking

With IoT technologies, you can create a smart warehouse with the ability to remotely control inventory assets. These capabilities help prevent under- or overloading, monitor the fuel level and the condition of goods, and can easily locate the goods on their way to the warehouse, port, or end customer.

5 Reasons Why Your Business Needs a Mobile eCommerce Application

5 Reasons Why Your Business Needs a Mobile eCommerce Application Using Salesforce to Improve Your Sales Pipeline: Five Tips

Using Salesforce to Improve Your Sales Pipeline: Five Tips Cross-Platform Mobile Development: Five Best Frameworks

Cross-Platform Mobile Development: Five Best Frameworks How to Develop Custom Accounting Software

How to Develop Custom Accounting Software 10 Best Web Development Frameworks in 2024

10 Best Web Development Frameworks in 2024

Top 30 Ecommerce Tools to Elevate Your Business in 2024

Top 30 Ecommerce Tools to Elevate Your Business in 2024 5 Best Tools to Improve Embedded Software Testing

5 Best Tools to Improve Embedded Software Testing Why React and Node.js Are the Top Technologies for Creating High-Performance Web Apps in 2024

Why React and Node.js Are the Top Technologies for Creating High-Performance Web Apps in 2024 10 Best IoT Platforms for 2024

10 Best IoT Platforms for 2024

Thanks for the article, it has valuable information. I came across the report, which details the IoT things on logistics.

I am reading this impressive article to increase my experience! Looking for all information about IoT!

Ꮩery good article! I’m really interested IoT theme, thanks!

Here, you explained IoT in logistics trends in a detailed manner.

Thanks for sharing!

Great idea to leverage IoT’s huge potential in different industries. It is only a matter of time when IoT will be incorporated in all spheres of our lives.

Nice article! Thank you. Now I know more about the applications of IoT in logistics. I thought that IoT was mostly implemented for personal use, such as smart home devices, etc.

I’m not sure about IoT technologies in the logistics sector. What bothers me is the protection of sensitive data. I think it is not perfect and still has a lot of space for improvement.

Wow, this is a great post. I loved reading this blog, and it is very informative. I wasn’t sure about Iot Solutions as it is new, and there has been not much awareness about this technology. Still, after reading this blog, I understand it correctly and the various application of Iot Solutions in multiple industries. Keep up the Good Work!

Are there any companies left that still use obsolete analog technologies? We transferred our whole infrastructure to an IoT-based one a few years ago, and I couldn’t ask for a better system.

Thanks for sharing such a logistics content!

The emerging Ecommerce industry and government favorable transportation policies are prominent growth factors of the connected logistics market. The adoption of IoT in logistics services is transforming existing logistics into digital logistics.

IoT seems to be a proper solution to existing logistics problems. It is very convenient when you can track the goods and monitor their state to ensure safe and timely delivery.

Hello Maryia! It is a most informative article about the digitalization of the Logistics world. In this competitive world, IoT in logistics is another step to make it reliable and fast processing. Furthermore, the value of IoT is expected to grow every year. Thanks for explaining the advantages and applications of IoT in logistics. Keep on posting.

Being a warehouse manager, I would truly appreciate IoT technology implementation at my facility. I always have issues with monitoring the condition of stored goods. I can’t wait for my company to finally implement IoT!

I have been working in the logistics industry for more than 5 years, and I can assure you that IoT technology has brought a lot of advantages to my daily work.