When it first emerged on the global IT market, Internet of Things technology caused a sensation. Internet of Things (IoT) solutions have proved to successfully revolutionize the ways that business is conducted across a multitude of various industrial domains on the worldwide level. In this article, we will focus on using IoT in inventory management. Read on to explore it in more detail.

What Is IoT and Inventory Management?

Internet of Things (IoT) represents correlated systems that include smart devices equipped with sensors, software, and other technologies that can receive, process, and transfer data via the internet without human intervention.

Leverage the latest IoT technologies with our expert team and get powerful IoT solution for your business.

Sensors constantly transfer data on the current state of the active devices in real-time. Based on their unique configuration, they can adjust their functionalities according to pre-set requirements. For example, if products stored in a warehouse are overheated, the IoT sensors can send signals to the IoT-based thermostat system in order to cool the temperature down.

IoT inventory management refers to the supervision of numerous processes when the managers order, store, use, transport, and sell the firm’s inventories. All these activities may include work with raw materials, constituent elements, and/or ready-made products.

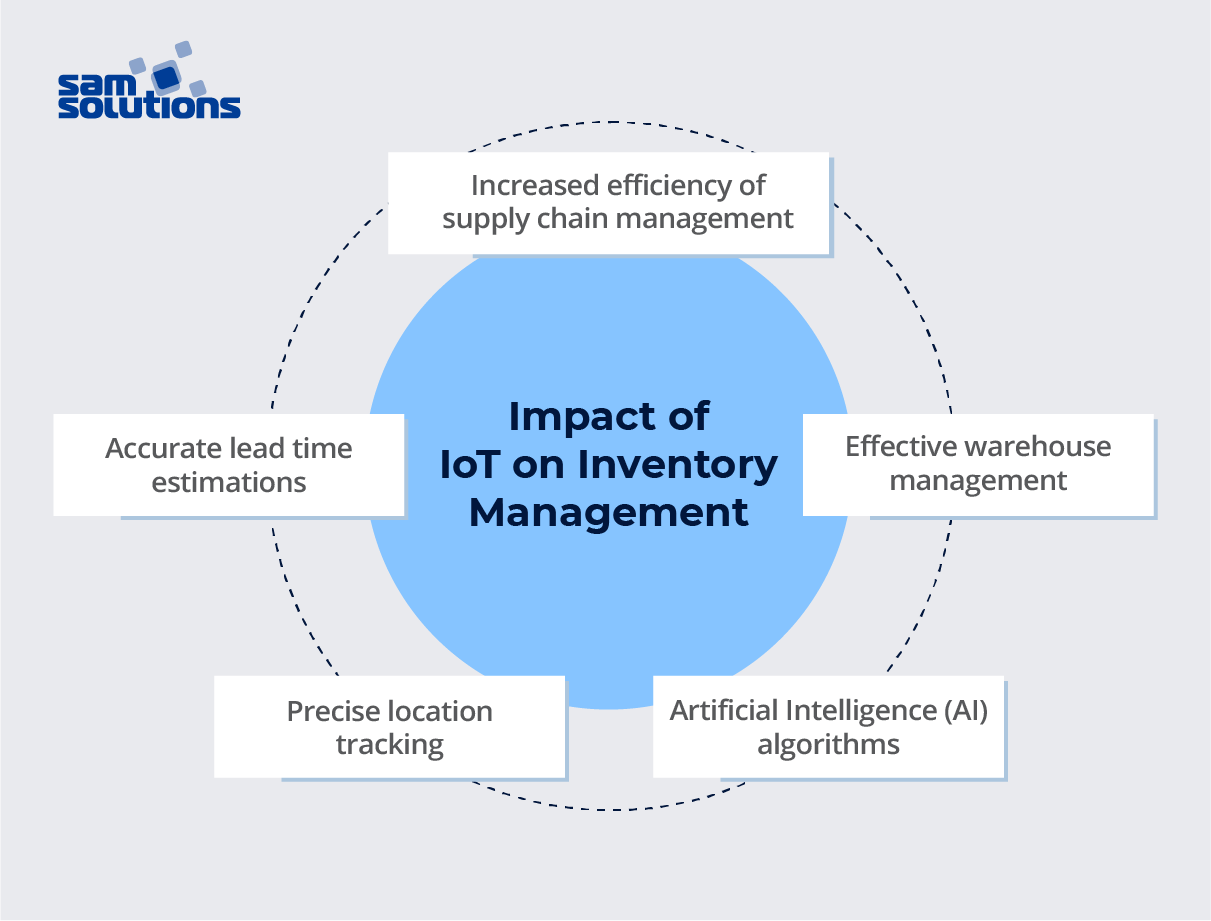

Impact of IoT on Inventory Management

Increased Efficiency of Supply Chain Management

With the help of IoT-based devices, specialists utilize a number of technologies to collect and manage data in a touchless way. The most widespread technologies include Global Positioning System (GPS) and Radio-frequency identification (RFID).

Such systems are well-equipped with special chips, smart devices, and mobile sensors that carry out effective monitoring and verification activities. Their aim is to ensure that all stages of the process are in order. Thanks to the huge amounts of data kept on IoT devices, the processes in companies have become more transparent, and it’s become easier for managers to track them.

Effective Warehouse Management

The development of IoT-oriented technologies have proven to be really advantageous for the enhancement of warehouse management. In essence, all warehouse management activities are aimed at optimizing storage – creating efficient space allocation and a convenient plan for product storage. For example, products that are rarely used are stored farther than those that are used more often. As a result, this method of space allocation makes accessing them quicker and easier.

Artificial Intelligence Algorithms

With the rise of artificial intelligence (AI) and machine learning, smart algorithms are now able to facilitate all tracking and control activities when dealing with inventory management. These modern technologies can do it better than human beings – they are faster, tireless, and more accurate.

AI is a great tool to discover tendencies on the IT market, as it can effectively analyze huge amounts of data. IoT inventory management specialists can make better decisions based on the results of such thorough research and even protect equipment with such innovative methods as ML-based predictive maintenance. In addition, AI systems can assist in multiple routine tasks at IoT inventory management facilities, such as replacing orders or identifying missing items.

Precise Location Tracking

IoT tools allow more precision while tracking the location of items. If products are equipped with IoT tracking systems, it helps store, move, and deliver them more efficiently. IoT inventory management upgrades the tracking process.

It offers the opportunity to monitor the transfer of products and plan their routes more thoroughly with the help of smart devices. For example, in case of a delay, managers can easily detect when and why the shipping process was disrupted. The analysis of such situations can upgrade the supply chain strategy and find new ways to make the delivery process faster.

Accurate Lead Time Estimation

IoT inventory management allows effective tracking, which is vital when it comes to lead time estimation. With Internet of Things technologies, it becomes possible to calculate the time allocated for final production.

If the assembling activities take a good deal of time, managers should consider time optimization in order to reveal the pitfalls and problems that are to be eliminated. As a result, the operations become more synchronized and effective, which subsequently leads to decreased lead time and driving down costs.

What Are the Benefits of an IoT Approach?

Internet of Things is a revolutionary technology that’s helping to drive the increasingly complex digitization of manufacturing facilities. In the below sections, we will explore the most significant benefits that IoT inventory management may bring to an organization.

Automated Inventory Tracking

RFID instruments spare IoT inventory management specialists from time-consuming routine tasks. In order to track and report on updates, they do not need to do it manually. The IoT system tracks the data and records it to the big data warehouse without human intervention. With such a high level of automation, IoT systems reduce the chance of human-made errors, and save both time and money.

Visible Inventory Characteristics

With IoT technologies, inventory management specialists can ensure that all the processes are highly visible and transparent to all interested parties. You can easily monitor how many items are being produced, stored, or transported in real-time, as well as track their location and state.

When an item leaves a department and moves to the next stage of the production process, this change is instantly reflected in the management system so that the IoT inventory management specialists can see the updates and make relevant decisions if necessary.

Enhanced Inventory Control

It is essential for inventory management specialists to have a clear view of the situation regarding all their products’ location and current status. If they don’t possess such knowledge, it will be hard to find the necessary items when the time comes. If the inventories are in order, it is possible to control the number of available items, avoid a probable shortage, and always meet the demand of the clients.

Bottleneck Analysis

Smart devices provide a thorough description and analysis on the state of all items at a facility. Based on this comprehensive information, managers can unveil all the obstacles that block the manufacturing process and disrupt smooth workflows. With this knowledge, it becomes possible to optimize the processes, making them faster and more efficient.

Optimized Lead Time

As a result of an increased awareness of all the details of inventory such as their number, location, and state, managers are able to make more weighted decisions to improve the production process. Consequently, the lead time is optimized, which leads to a more cost-efficient approach to manufacturing.

Besides, with such groundbreaking innovations as predictive analytics, machine learning algorithms can predict the possible demand and specialists can then adjust the resources accordingly.

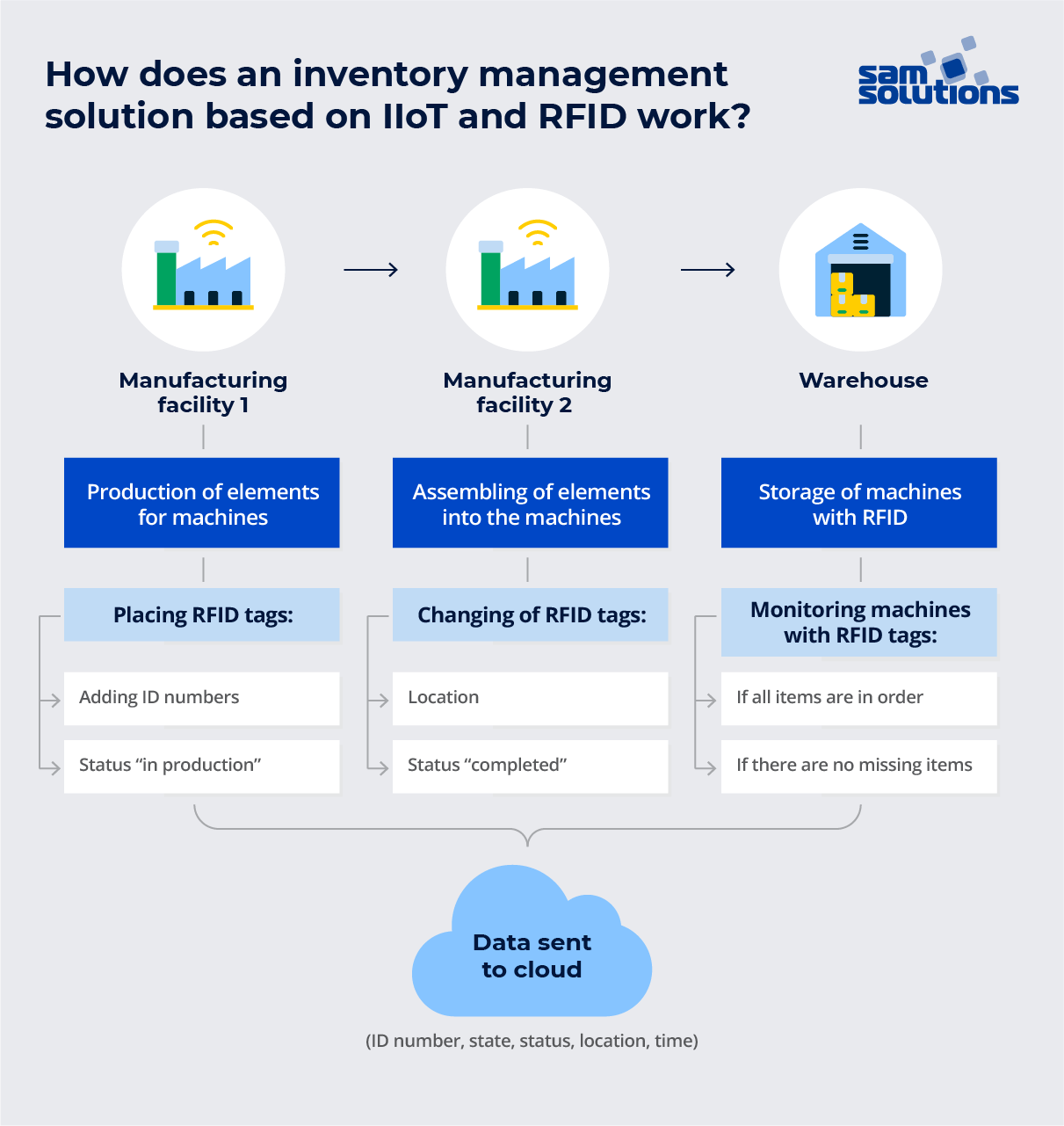

How Does an Inventory Management Solution Based on IIoT and RFID Work?

In order to shed more light on the functioning of IoT smart inventory management, we would consider the example of the following industrial manufacturing process. Imagine the manufacturing company has two facilities: one for building the elements for machines, and another for their assembling.

At the very start of such a process, the elements get passive RFID tags. All tags have one-of-a-kind identification numbers which have data about all of the parts. The identification numbers are kept in the associated big data warehouse.

All the elements with a tag undergo several stages of processing at the manufacturing facility. During this process, the RFID reader scans the tags which serves to relay the identification numbers and all the data about the location of elements to cloud storage.

Then, the cloud conveys the analysis of the received data and determines the location and status of every numbered element. If the element is absent, a notification is sent to the user along with the setting of a special status “missing” to the IoT-based inventory management solution. When the system identifies the location of the element, the status is changed back to the initial “in production.”

When the elements are ready, the managers ship them to the assembling area. Prior to departure, specialists scan the elements with RFID to control the number of elements that are sent to the next stage. Then, after the arrival of the elements to the assembling facility, one more RFID reading occurs to make sure that all items were successfully delivered.

Then, the elements are assembled at the manufacturing facility and all ready-made machines get new tags. The old tags on the elements can be either kept or removed depending on the production requirements. When the machines are moved through the departments, each tag is scanned and the data is sent to the cloud for exact location identification.

The next step is shipping to the storehouse. There, tags are scanned again to detect if all the items are in order and there are no absent tags. In this way, the elements are tracked all the way through their manufacturing, assembling, and storage process till they reach their end consumer. Thanks to this constant tracking with the RFID tagging system, manufacturing companies can ensure a high level of production and comprehensive control at every stage of their production process.

Challenges of IoT in Inventory Management

Although IoT offers a multitude of benefits for inventory management, it can bring some challenges and limitations as well. Foremost, as specialists attach RFID tags to the products that are still in progress, it is necessary to guarantee that their presence doesn’t affect manufacturing procedures.

Another problem is the potentially problematic process of scanning, especially with such substances as liquids and metals. When specialists try to do scanning through such barriers, the reading tends to be incorrect. Also, the price of IoT equipment is pretty expensive. Whereas all business expenditures should be feasible to implement them, it’s important to evaluate if the final product is priced high enough to justify the paid expenses.

Some companies are reluctant to implement IoT in their workflows, because they are not sure if it will be safe enough. As any other software solution for businesses, this can be a vulnerable target for cyberattackers. Bearing this in mind, business owners should pay close attention to proper security activities in order to protect their systems. Luckily, there are plenty of ways to ensure a high level of security, such as blockchain-based IoT applications that possess multiple layers of protection.

Logistical activities may be an issue too, as manufacturers experience loss due to spoiled or lost products. However, this is not the problem that only IoT-based inventory management software may face, as all manufacturing facilities suffer from it the same. In order to solve this issue, IoT technology provides tracking and monitoring equipment to safeguard the property.

To perform efficient IoT inventory management, companies need enough data for proper data analysis and strategic planning. With IoT solutions, this becomes possible.

Popular Brands that Have Implemented IoT for Inventory Management

Amazon

Being a huge international tech firm, Amazon pays a lot of attention to eCommerce and retail solutions, cloud, AI, and digital transformation technologies. Warehouse management in the company is based on IoT solutions that include robotics, automated scanning, and transportation. The IoT activities facilitate smooth and stable workflows, and free the workforce to do less routine and more creative tasks.

DHL

DHL is a well-known company in the logistics sector. It specializes in multinational delivery across almost all of the globe. As a renowned brand in the field, the company needs to provide fast, top-quality services to their clients. In order to meet this goal, they enriched their workflows with automated IoT systems that assist in their procedures. Their technologies include drone systems, robotics, and advanced smart devices that make their work more accurate and productive.

Alibaba

Alibaba is a large brand in the eCommerce industry. Being a leading company for online sales in the global market, it needed effective modern solutions to optimize their internal processes and offer first-rate services to their clients. After implementing IoT in their work processes, they excel at trouble-free and quick delivery. This was a result of utilizing automated warehouse systems and IoT-based inventory management.

Why Should I Order IoT Services from SaM Solutions

With decades of experience, SaM Solutions has gained deep expertise in building functional performant IoT projects. We have successfully delivered IoT-based solutions for businesses of various domains across the entire globe. Our expertise allows us to take on especially challenging projects and help companies thrive in their industries with the help of advanced IoT solutions.

Our IoT services include end-to-end custom development of IoT-based solutions, cloud development, consulting and audits, migration and integration, replatforming, optimization, troubleshooting, maintenance, and support.

A good example of one of our IoT-based solutions is the Smart Delivery Box that we created for Sun E Mates. This IoT solution helps to ensure physical safety of parcel shipments, and protects the packages against theft and extreme weather conditions. In close cooperation with the creators behind this idea, we helped the company bring their vision to life.

Thanks to the talented specialists of our company, we deliver modern IoT-based solutions of excellent quality and security. Committed to the idea of project success, we meet and exceed customer expectations. We would be glad to help you with your IoT project. If you are interested to learn more, please feel free to contact our team.

Conclusions

Inventory management can benefit greatly from enhancement with forward-looking IoT technologies. Thanks to such top-notch solutions, it becomes possible to monitor work processes efficiently, collect and transmit data in real time, control the state of the products, and make more weighted decisions. It is a cost-effective way to upgrade the workflows and optimize inventory management, leading to better customer service and increasing an organization’s competitiveness.

The Latest 15 Information Technology Trends in 2024

The Latest 15 Information Technology Trends in 2024 Top 10 Embedded Software Development Tools

Top 10 Embedded Software Development Tools IaaS vs. PaaS vs. SaaS: What’s the Difference?

IaaS vs. PaaS vs. SaaS: What’s the Difference? IoT Development: Top 15 Internet of Things Tools and Platforms in 2024

IoT Development: Top 15 Internet of Things Tools and Platforms in 2024 10 Examples of Predictive Analytics

10 Examples of Predictive Analytics

MACH Technology: What Is It?

MACH Technology: What Is It? The 16 Best .NET Development Tools

The 16 Best .NET Development Tools How to Create Your Own CRM System: A Step-by-Step Guide

How to Create Your Own CRM System: A Step-by-Step Guide How to Create Artificial Intelligence Software

How to Create Artificial Intelligence Software The Ultimate Guide to Conducting an Audit of Your Ecommerce Website

The Ultimate Guide to Conducting an Audit of Your Ecommerce Website

I do not agree that AI can pose any threat. As I see it, there are only positive possible outcomes of such perspective. AI can substitute many work positions, but it will not replace all of them. It is well-known, that robots can not perform any unique tasks, but only act according to the pre-set programs. Even when we speak about neural networks that create art objects, they are not entirely unique, as they are based on the masterpieces of human artists. So I think they are not our rivals, but rather great allies and assistants.

Well, I agree that AI will soon replace the human workforce. The mankind is on the threshold of total tech revolution, which will transform the world as we see it now. However, I fear that AI will soon conquer the world.

I think we humans should give more power to AI and robots. They are impartial and indisposed to fatigue and human-made errors. I am sure that artificial intelligence has a bright future across many industries.

Thanks for the description of utilizing IoT in the inventory management activities. I think it would be a great idea to implement it for my business in the future.

Predictive maintenance service is really impressive. Once I had experience with this technology, when we installed a system that was able to conduct real-time monitoring of the assets’ state without human control.

We have tried IoT for managing inventories. As a result, we faced tremendous increase in productivity and efficiency, as the workflows became smoother and safer in comparison with what we had earlier.

I run eCommece business and currently I am in dire need of effective inventory management. I heard about IoT, but never tried it before. I think I am eager to give it a shot now.